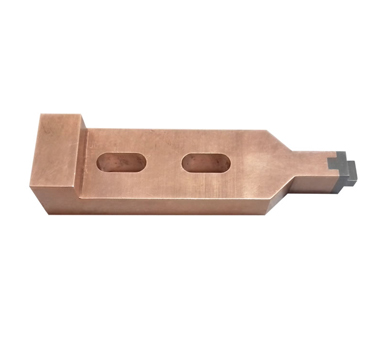

Spot Welding Electrodes

For over 35 years, MZ Usinagem has specialized in manufacturing and recovering spot welding electrodes. The pieces are custom-made according to the customer's request in different materials such as:

- Tungsten and tungsten alloys

- Pure copper and copper alloys

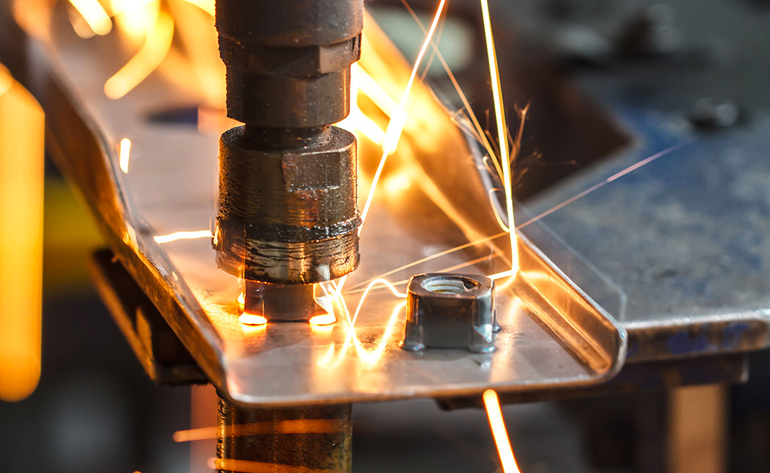

The process uses two electrodes, made of different materials (tailor-made), which concentrate current in a small "point" and in a very short time (about 10 to 100 milliseconds), trapping the desired materials. This allows welding to take place without overheating the rest of the material/part.

The amount of energy is chosen to be compatible with material properties, joint thickness and electrode type. These welding processes are widely used in the industry, mainly because they allow high productivity and low operating costs.

Electrode Holder

MZ Usinagem is a reference in the manufacture of electrode holders, equipment that serves to give security to the weld, allowing its correct fixation and efficient work.

Our products are a national reference, being manufactured within the highest quality standards, offering safety, great resistance, high durability and easy maintenance.